View All Use Cases

Click below to navigate through the power of AI for your business

- Problems We Solve

- Unmeasurable Operator Inefficiency

- Unknown Downtime

- Unexplained Losses

- Unidentifiable Waste

- Unseen Safety Risks

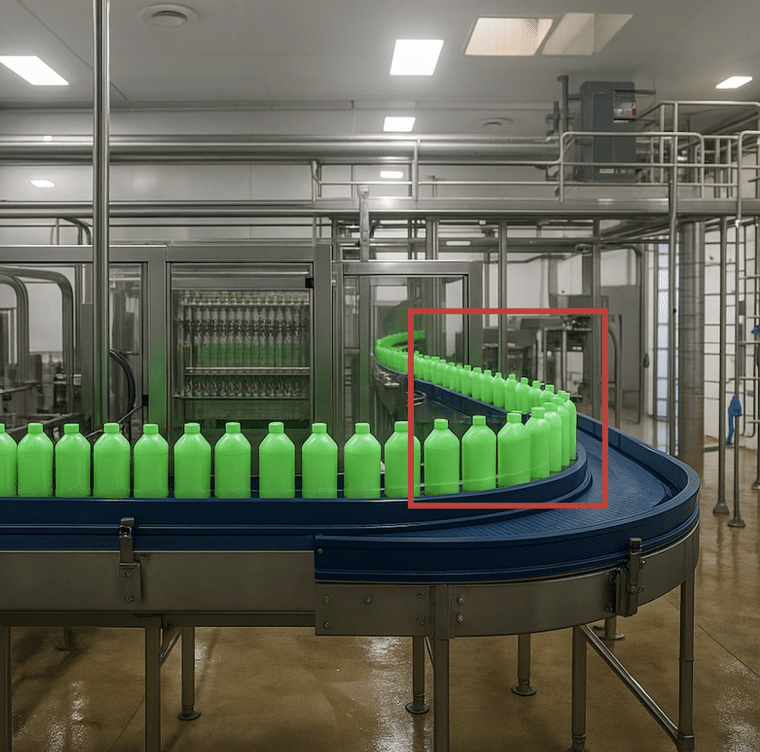

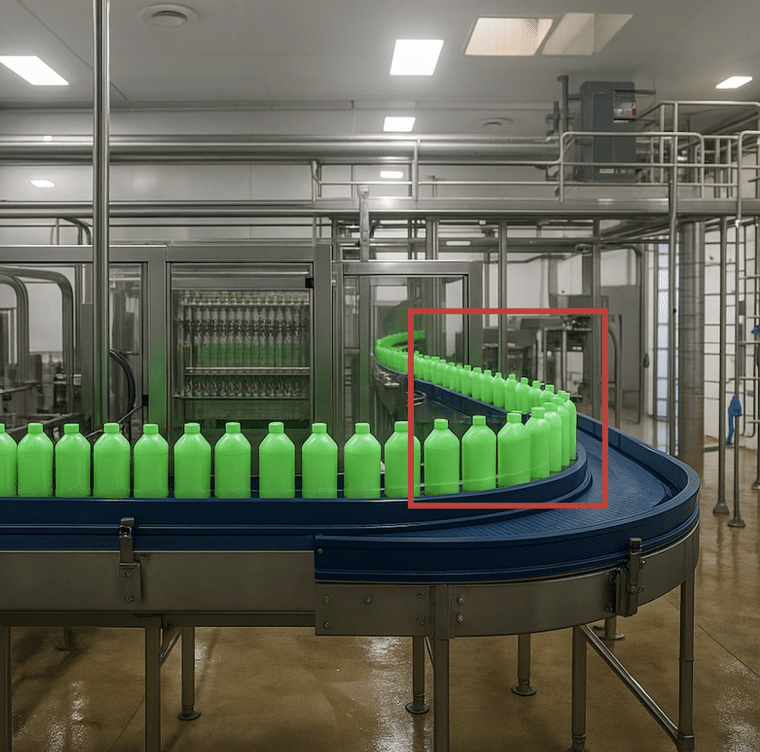

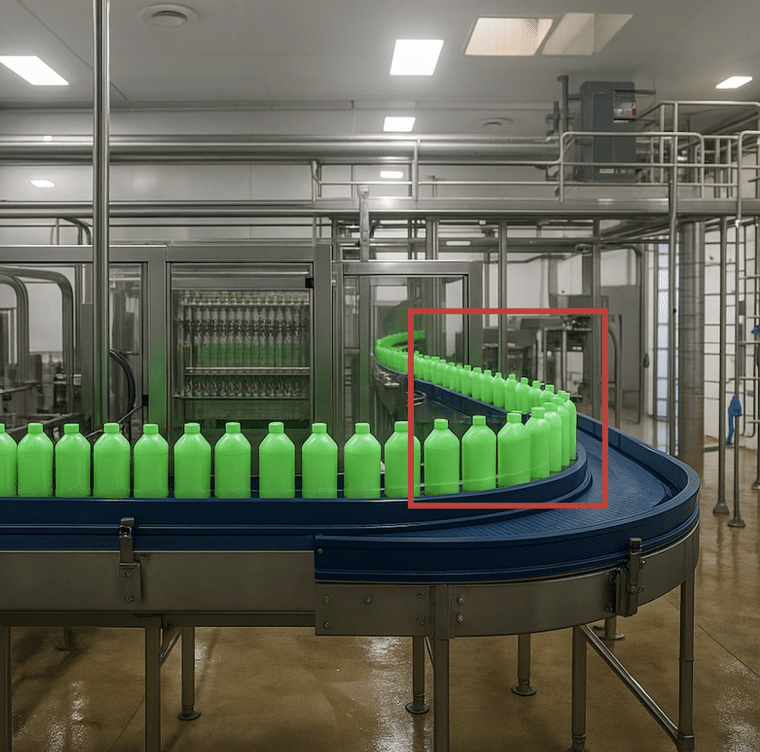

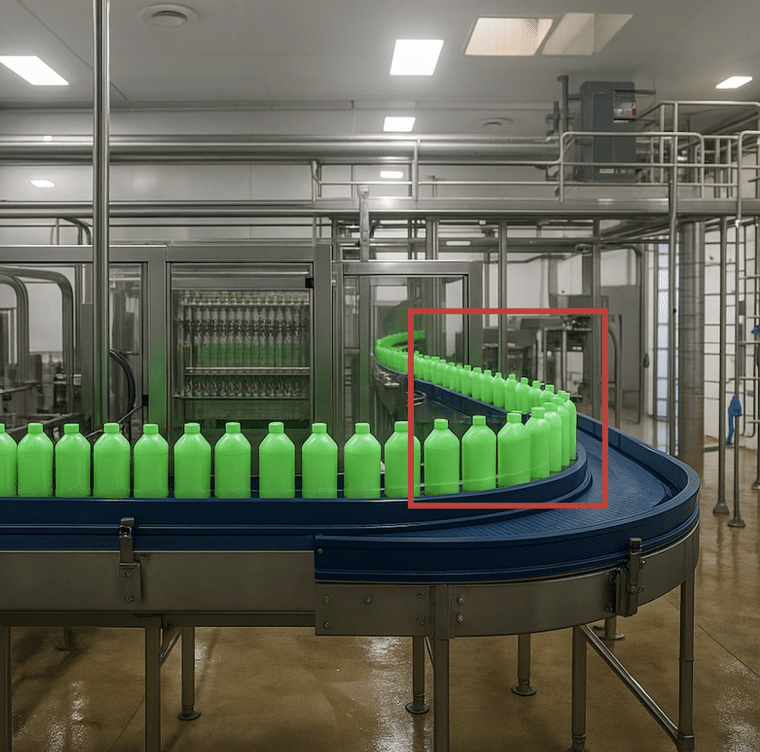

Quality Control for Packaging Defect Detection

Packaging defects are a major driver of OEE quality losses, yet many go undetected until it’s too late. Real-time packaging defect detection using existing factory CCTV enables consistent quality control across the line, catching defects early and preventing waste, rework, and downtime.

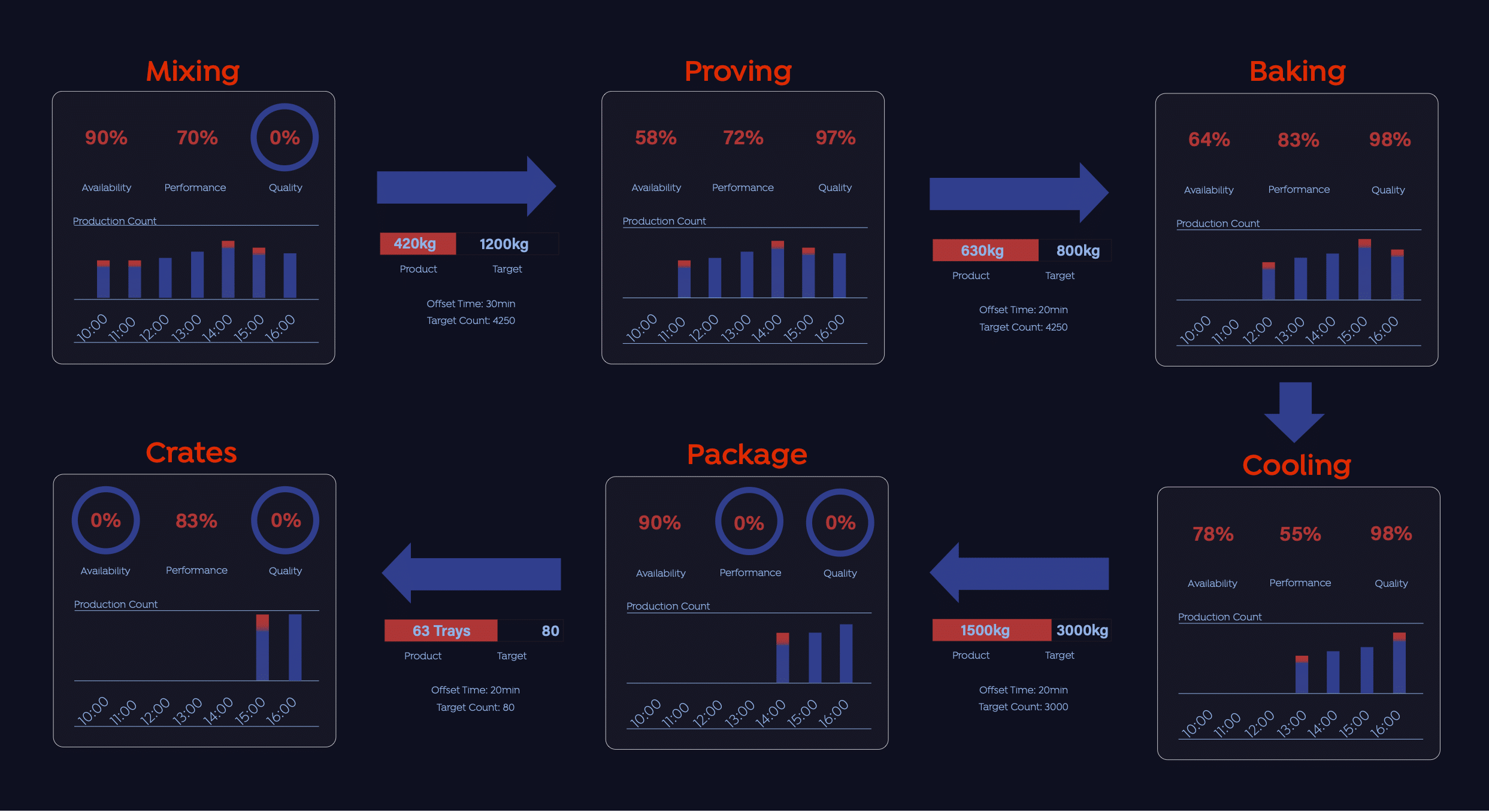

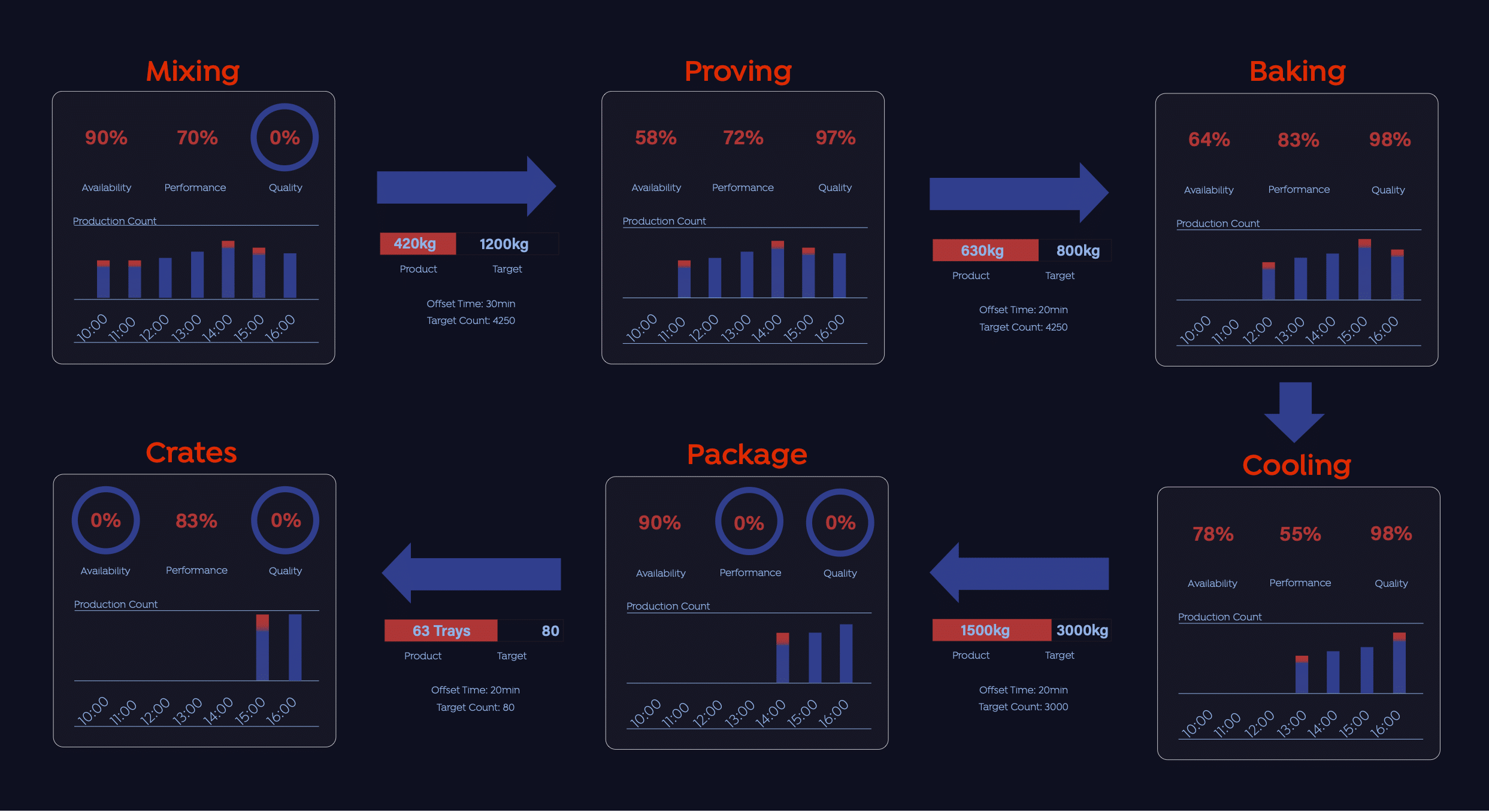

Real Time OEE Monitoring to Expose Hidden Performance Losses

Manual OEE reporting hides the biggest performance losses on the line. Real-time OEE monitoring using existing factory CCTV, exposes microstoppages, slowdowns, and performance drift as they happen, enabling immediate corrective action and measurable OEE improvement.

Real-Time Forklift Safety Monitoring for 3-Meter Rule Compliance

Real-time forklift safety monitoring that uses AI and existing CCTV to enforce the 3-meter rule, reduce near misses, and improve workplace safety compliance.

Quality Assurance and Quality Control in Industrial Bakeries

Quality assurance and quality control in industrial bakery operations using real time camera monitoring to detect defects early, reduce waste, improve OEE, and deliver root cause insight across production lines.

Bakery Line Product Monitoring with SKU Accuracy

Bakery line product monitoring with SKU accuracy using real time camera intelligence to classify products, reduce manual reconciliation, expose SKU driven OEE losses, prevent mixed batches, and improve quality consistency across high speed production lines.

Downtime Monitoring Solution Cuts Microstoppages in Food Production

Reduce microstoppages with downtime monitoring solutions. Gain real-time visibility, identify root causes, and increase efficiency without new hardware.

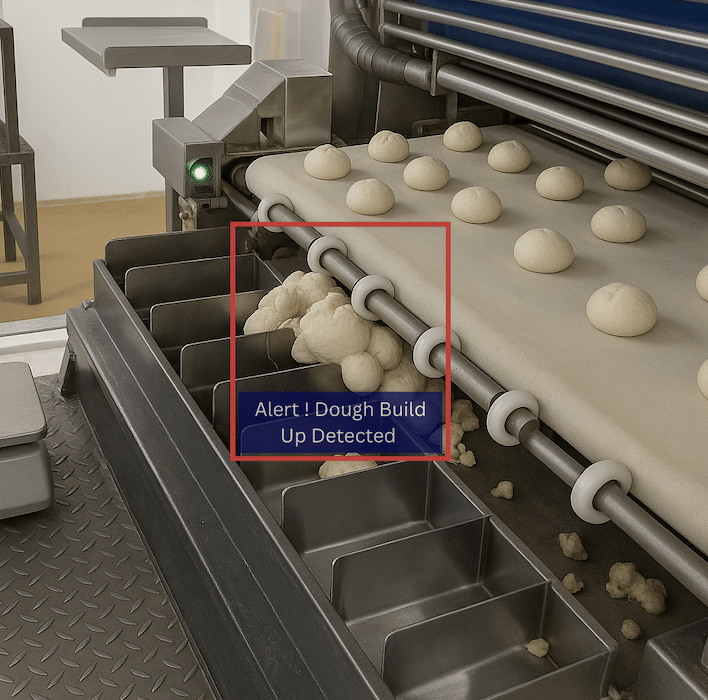

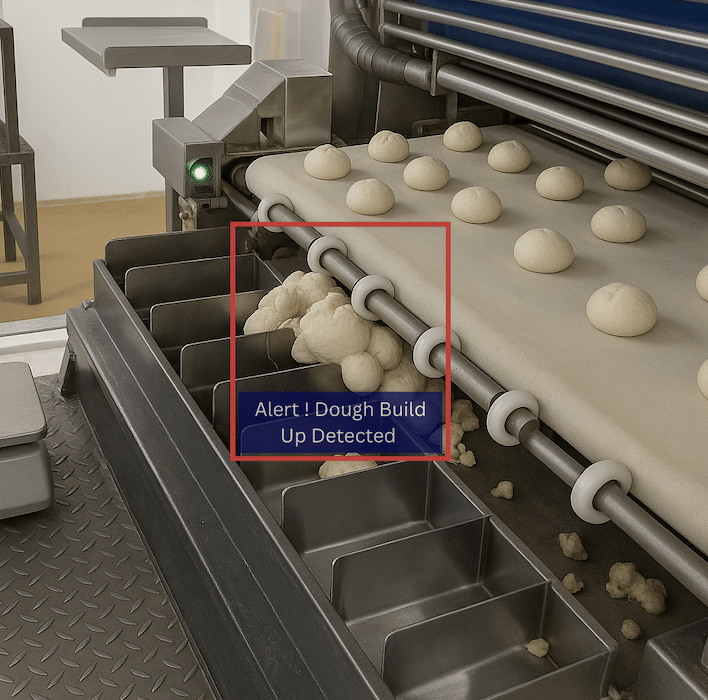

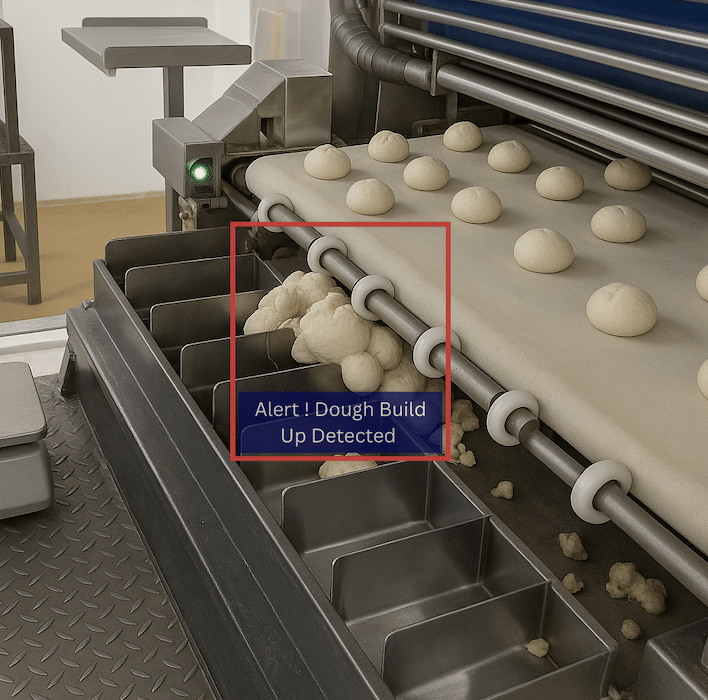

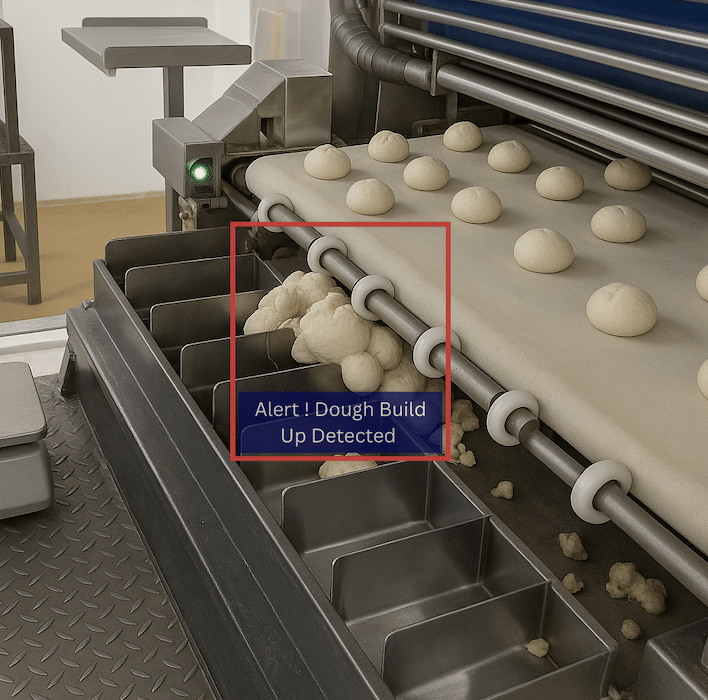

Real-Time Bakery Equipment Monitoring for Industrial Bakeries

Real-time bakery equipment monitoring for industrial baking detects early dough build-up, reduces downtime and waste, stabilises performance, protects quality, and improves OEE across production lines.

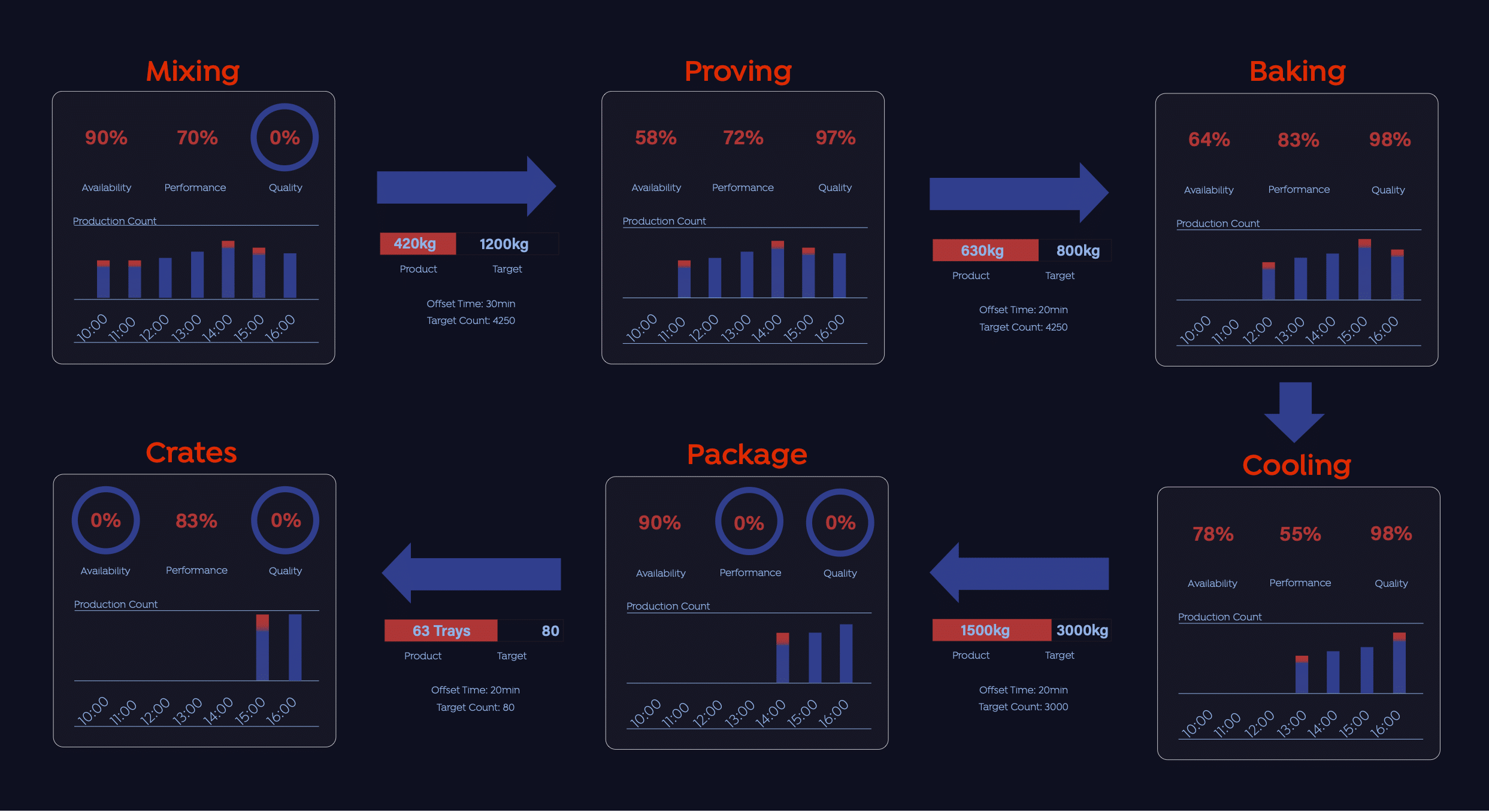

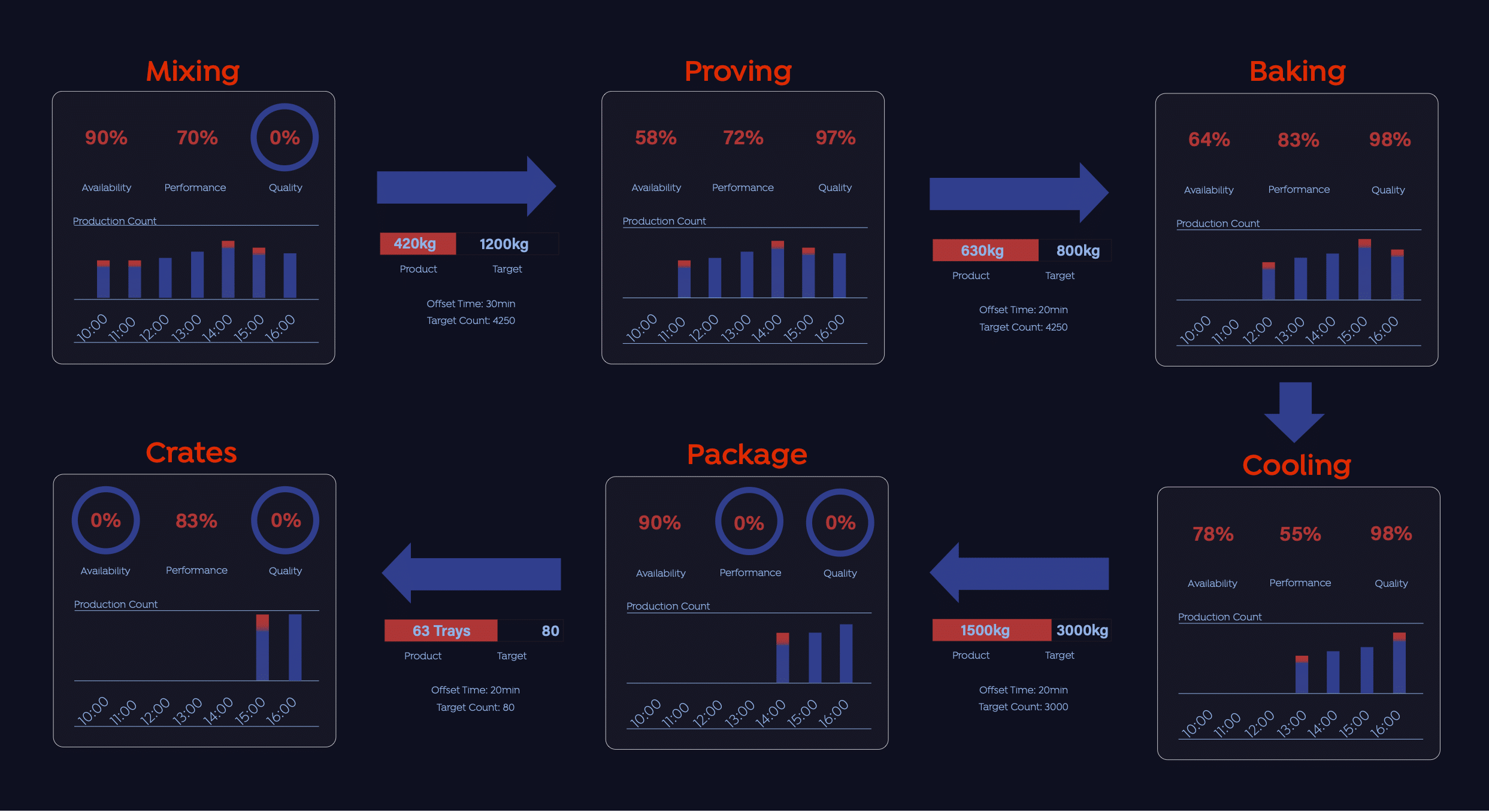

Efficient Bakery Production Line Eliminates Blind Spots and Boosts Performance

Efficient bakery production line visibility using real time camera monitoring to remove blind spots, improve availability, stabilise performance, prevent quality losses, and lift OEE across high speed baking operations.

Heavy Goods Vehicle (HGV) Truck Load Safety Using Visual AI & GPT

Implementing HGV truck load safety measures and protocols is imperative to mitigate risks, prevent injuries, and safeguard lives.

Sinter Plant Condition Monitoring for Early Defect Detection

Sinter plant condition monitoring using real time camera detection to identify firebar, sidewall, and seal pad defects early, reduce downtime, stabilise gas flow, protect OEE, and improve blast furnace performance.

Final Inspection Monitoring to Improve Labor Efficiency

Final inspection monitoring that improves labor efficiency by detecting operator inactivity, packing delays, and bottlenecks before they impact production throughput.

Food Production Efficiency and Risk Mitigation on Pre-Batch Processes

The pre-batch step in food manufacturing is to ensure food products are made up of the right quantities of the right ingredients

Stamping out Cross-Contamination in Food Manufacturing

AI offers a comprehensive view of the entire production process, enabling quicker identification and rectification of quality issues

Real-Time Productivity Monitoring Across Factory Workstations

Real-time productivity monitoring across factory workstations using AI and existing CCTV to track operator activity, identify idle time, and improve labor efficiency and compliance.

Preventing Agricultural Fraud and Ensuring Accurate Deliveries

VisionTrack offers an advanced computer vision solution tracking to help organizations reduce agricultural fraud with AI.

Maximizing Machine Utilization in Manufacturing

Manufacturing organizations rely on expensive, critical machinery to maintain optimal production levels and profitability.

Quality Control for Bread Manufacturing

The visionAI system requires significantly less staff, produces more accurate results, and forms the backbone of an integrated system that affects more than just the bread stock losses.

Quality Assurance for Food Manufacturing Defect Detection

Quality assurance for food manufacturing defect detection using real time camera monitoring to identify empty and underfilled pies, reduce waste, improve consistency, and stop defects before they move downstream.

Final Inspection Monitoring to Improve Labor Efficiency

Final inspection monitoring that improves labor efficiency by detecting operator inactivity, packing delays, and bottlenecks before they impact production throughput.

Real-Time Productivity Monitoring Across Factory Workstations

Real-time productivity monitoring across factory workstations using AI and existing CCTV to track operator activity, identify idle time, and improve labor efficiency and compliance.

Real Time OEE Monitoring to Expose Hidden Performance Losses

Manual OEE reporting hides the biggest performance losses on the line. Real-time OEE monitoring using existing factory CCTV, exposes microstoppages, slowdowns, and performance drift as they happen, enabling immediate corrective action and measurable OEE improvement.

Bakery Line Product Monitoring with SKU Accuracy

Bakery line product monitoring with SKU accuracy using real time camera intelligence to classify products, reduce manual reconciliation, expose SKU driven OEE losses, prevent mixed batches, and improve quality consistency across high speed production lines.

Downtime Monitoring Solution Cuts Microstoppages in Food Production

Reduce microstoppages with downtime monitoring solutions. Gain real-time visibility, identify root causes, and increase efficiency without new hardware.

Real-Time Bakery Equipment Monitoring for Industrial Bakeries

Real-time bakery equipment monitoring for industrial baking detects early dough build-up, reduces downtime and waste, stabilises performance, protects quality, and improves OEE across production lines.

Sinter Plant Condition Monitoring for Early Defect Detection

Sinter plant condition monitoring using real time camera detection to identify firebar, sidewall, and seal pad defects early, reduce downtime, stabilise gas flow, protect OEE, and improve blast furnace performance.

Maximizing Machine Utilization in Manufacturing

Manufacturing organizations rely on expensive, critical machinery to maintain optimal production levels and profitability.

Preventing Agricultural Fraud and Ensuring Accurate Deliveries

VisionTrack offers an advanced computer vision solution tracking to help organizations reduce agricultural fraud with AI.

Quality Control for Packaging Defect Detection

Packaging defects are a major driver of OEE quality losses, yet many go undetected until it’s too late. Real-time packaging defect detection using existing factory CCTV enables consistent quality control across the line, catching defects early and preventing waste, rework, and downtime.

Quality Assurance and Quality Control in Industrial Bakeries

Quality assurance and quality control in industrial bakery operations using real time camera monitoring to detect defects early, reduce waste, improve OEE, and deliver root cause insight across production lines.

Efficient Bakery Production Line Eliminates Blind Spots and Boosts Performance

Efficient bakery production line visibility using real time camera monitoring to remove blind spots, improve availability, stabilise performance, prevent quality losses, and lift OEE across high speed baking operations.

Quality Control for Bread Manufacturing

The visionAI system requires significantly less staff, produces more accurate results, and forms the backbone of an integrated system that affects more than just the bread stock losses.

Quality Assurance for Food Manufacturing Defect Detection

Quality assurance for food manufacturing defect detection using real time camera monitoring to identify empty and underfilled pies, reduce waste, improve consistency, and stop defects before they move downstream.

Real-Time Forklift Safety Monitoring for 3-Meter Rule Compliance

Real-time forklift safety monitoring that uses AI and existing CCTV to enforce the 3-meter rule, reduce near misses, and improve workplace safety compliance.

Heavy Goods Vehicle (HGV) Truck Load Safety Using Visual AI & GPT

Implementing HGV truck load safety measures and protocols is imperative to mitigate risks, prevent injuries, and safeguard lives.

Food Production Efficiency and Risk Mitigation on Pre-Batch Processes

The pre-batch step in food manufacturing is to ensure food products are made up of the right quantities of the right ingredients

Stamping out Cross-Contamination in Food Manufacturing

AI offers a comprehensive view of the entire production process, enabling quicker identification and rectification of quality issues

- Industries We Serve

- Agriculture

- Discrete Manufacturing

- Food & Beverage Manufacturing

- Industrial Baking

- Steel Manufacturing

- Workplace Health & Safety

Quality Control for Packaging Defect Detection

Packaging defects are a major driver of OEE quality losses, yet many go undetected until it’s too late. Real-time packaging defect detection using existing factory CCTV enables consistent quality control across the line, catching defects early and preventing waste, rework, and downtime.

Real Time OEE Monitoring to Expose Hidden Performance Losses

Manual OEE reporting hides the biggest performance losses on the line. Real-time OEE monitoring using existing factory CCTV, exposes microstoppages, slowdowns, and performance drift as they happen, enabling immediate corrective action and measurable OEE improvement.

Real-Time Forklift Safety Monitoring for 3-Meter Rule Compliance

Real-time forklift safety monitoring that uses AI and existing CCTV to enforce the 3-meter rule, reduce near misses, and improve workplace safety compliance.

Quality Assurance and Quality Control in Industrial Bakeries

Quality assurance and quality control in industrial bakery operations using real time camera monitoring to detect defects early, reduce waste, improve OEE, and deliver root cause insight across production lines.

Bakery Line Product Monitoring with SKU Accuracy

Bakery line product monitoring with SKU accuracy using real time camera intelligence to classify products, reduce manual reconciliation, expose SKU driven OEE losses, prevent mixed batches, and improve quality consistency across high speed production lines.

Downtime Monitoring Solution Cuts Microstoppages in Food Production

Reduce microstoppages with downtime monitoring solutions. Gain real-time visibility, identify root causes, and increase efficiency without new hardware.

Real-Time Bakery Equipment Monitoring for Industrial Bakeries

Real-time bakery equipment monitoring for industrial baking detects early dough build-up, reduces downtime and waste, stabilises performance, protects quality, and improves OEE across production lines.

Efficient Bakery Production Line Eliminates Blind Spots and Boosts Performance

Efficient bakery production line visibility using real time camera monitoring to remove blind spots, improve availability, stabilise performance, prevent quality losses, and lift OEE across high speed baking operations.

Heavy Goods Vehicle (HGV) Truck Load Safety Using Visual AI & GPT

Implementing HGV truck load safety measures and protocols is imperative to mitigate risks, prevent injuries, and safeguard lives.

Sinter Plant Condition Monitoring for Early Defect Detection

Sinter plant condition monitoring using real time camera detection to identify firebar, sidewall, and seal pad defects early, reduce downtime, stabilise gas flow, protect OEE, and improve blast furnace performance.

Final Inspection Monitoring to Improve Labor Efficiency

Final inspection monitoring that improves labor efficiency by detecting operator inactivity, packing delays, and bottlenecks before they impact production throughput.

Food Production Efficiency and Risk Mitigation on Pre-Batch Processes

The pre-batch step in food manufacturing is to ensure food products are made up of the right quantities of the right ingredients

Stamping out Cross-Contamination in Food Manufacturing

AI offers a comprehensive view of the entire production process, enabling quicker identification and rectification of quality issues

Real-Time Productivity Monitoring Across Factory Workstations

Real-time productivity monitoring across factory workstations using AI and existing CCTV to track operator activity, identify idle time, and improve labor efficiency and compliance.

Preventing Agricultural Fraud and Ensuring Accurate Deliveries

VisionTrack offers an advanced computer vision solution tracking to help organizations reduce agricultural fraud with AI.

Maximizing Machine Utilization in Manufacturing

Manufacturing organizations rely on expensive, critical machinery to maintain optimal production levels and profitability.

Quality Control for Bread Manufacturing

The visionAI system requires significantly less staff, produces more accurate results, and forms the backbone of an integrated system that affects more than just the bread stock losses.

Quality Assurance for Food Manufacturing Defect Detection

Quality assurance for food manufacturing defect detection using real time camera monitoring to identify empty and underfilled pies, reduce waste, improve consistency, and stop defects before they move downstream.

Preventing Agricultural Fraud and Ensuring Accurate Deliveries

VisionTrack offers an advanced computer vision solution tracking to help organizations reduce agricultural fraud with AI.

Final Inspection Monitoring to Improve Labor Efficiency

Final inspection monitoring that improves labor efficiency by detecting operator inactivity, packing delays, and bottlenecks before they impact production throughput.

Real-Time Productivity Monitoring Across Factory Workstations

Real-time productivity monitoring across factory workstations using AI and existing CCTV to track operator activity, identify idle time, and improve labor efficiency and compliance.

Maximizing Machine Utilization in Manufacturing

Manufacturing organizations rely on expensive, critical machinery to maintain optimal production levels and profitability.

Downtime Monitoring Solution Cuts Microstoppages in Food Production

Reduce microstoppages with downtime monitoring solutions. Gain real-time visibility, identify root causes, and increase efficiency without new hardware.

Food Production Efficiency and Risk Mitigation on Pre-Batch Processes

The pre-batch step in food manufacturing is to ensure food products are made up of the right quantities of the right ingredients

Stamping out Cross-Contamination in Food Manufacturing

AI offers a comprehensive view of the entire production process, enabling quicker identification and rectification of quality issues

Quality Assurance and Quality Control in Industrial Bakeries

Quality assurance and quality control in industrial bakery operations using real time camera monitoring to detect defects early, reduce waste, improve OEE, and deliver root cause insight across production lines.

Bakery Line Product Monitoring with SKU Accuracy

Bakery line product monitoring with SKU accuracy using real time camera intelligence to classify products, reduce manual reconciliation, expose SKU driven OEE losses, prevent mixed batches, and improve quality consistency across high speed production lines.

Real-Time Bakery Equipment Monitoring for Industrial Bakeries

Real-time bakery equipment monitoring for industrial baking detects early dough build-up, reduces downtime and waste, stabilises performance, protects quality, and improves OEE across production lines.

Efficient Bakery Production Line Eliminates Blind Spots and Boosts Performance

Efficient bakery production line visibility using real time camera monitoring to remove blind spots, improve availability, stabilise performance, prevent quality losses, and lift OEE across high speed baking operations.

Quality Control for Bread Manufacturing

The visionAI system requires significantly less staff, produces more accurate results, and forms the backbone of an integrated system that affects more than just the bread stock losses.

Quality Assurance for Food Manufacturing Defect Detection

Quality assurance for food manufacturing defect detection using real time camera monitoring to identify empty and underfilled pies, reduce waste, improve consistency, and stop defects before they move downstream.

Heavy Goods Vehicle (HGV) Truck Load Safety Using Visual AI & GPT

Implementing HGV truck load safety measures and protocols is imperative to mitigate risks, prevent injuries, and safeguard lives.

Sinter Plant Condition Monitoring for Early Defect Detection

Sinter plant condition monitoring using real time camera detection to identify firebar, sidewall, and seal pad defects early, reduce downtime, stabilise gas flow, protect OEE, and improve blast furnace performance.

Real-Time Forklift Safety Monitoring for 3-Meter Rule Compliance

Real-time forklift safety monitoring that uses AI and existing CCTV to enforce the 3-meter rule, reduce near misses, and improve workplace safety compliance.